Bryce C

DFW

And so do I! Now how do I keep this thing running? I've studied the manual, especially the maintenance section. I've ordered replacement belts for the pump and blower, as well as the appropriate oil for the water pump and blower. I already have the appropriate grease for the driveshaft and gave it a full greasing. I will keep up with regularly scheduled maintenance as per the manual's recommendations. Also it seems van maintenance like 1500k to 2000k oil changes and coolant system maintenance is important. I started a checklist in the van, ticking the boxes of what I have done with the engine hours and vehicle mileage marked next to them...

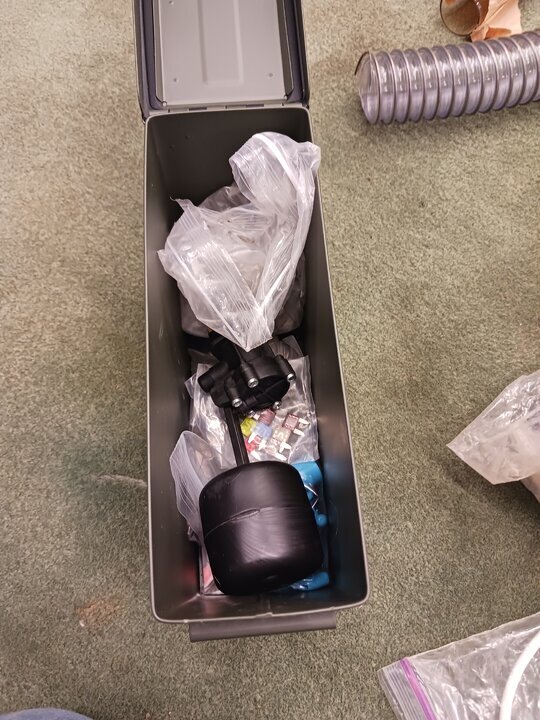

I have setup a pretty decent mobile toolkit too. But!!! There are a like a dozen different types of hoses and a hundred types of fittings in this thing. Not to mention the more expensive pumps, clutches, valves, etc... Aside from wand valve replacements, spare regulator valve, and male and female quick connects... Any recommendations as to what to carry with me for replaceable parts to be prepared for repairs while on the road? I was going through the manual parts catalog and was just going to order every small thing I could until I realized I'd spend thousands doing that. Maybe I should anyway I have a 2013 CDS 4.8. Any tips are much appreciated :]

I have a 2013 CDS 4.8. Any tips are much appreciated :]

I have setup a pretty decent mobile toolkit too. But!!! There are a like a dozen different types of hoses and a hundred types of fittings in this thing. Not to mention the more expensive pumps, clutches, valves, etc... Aside from wand valve replacements, spare regulator valve, and male and female quick connects... Any recommendations as to what to carry with me for replaceable parts to be prepared for repairs while on the road? I was going through the manual parts catalog and was just going to order every small thing I could until I realized I'd spend thousands doing that. Maybe I should anyway